-

Phone

86-512-58905519

-

Address

Leyu Town, Zhangjiagang City, Suzhou, Jiangsu, China

-

E-mail

Full Automatic 3 in 1 Pure Water Filling Plant

China Full Automatic 3 in 1 Pure Water Filling Plant, Find details about China Water Filling Machine, Filling Machine from Full Automatic 3 in 1 Pure Water Filling Plant - Zhangjiagang Sky Machine Co., Ltd.

Description

- Model NO.: CGF Series

- Automatic Grade: Automatic

- Filling Valve Head: Multi-Head

- Dosing Device: Plunger

- Packaging Container Lifting Structure: Pneumatic Lifting

- Packaging: Bottle

- Capacity: 1000bph-20000bph

- Main Material: SUS304/SUS316

- Washing Heads: 12-60

- Capping Heads: 4-15

- Warranty: 12months

- Trademark: Sky Machine

- Specification: CE Certificate/ ISO9000: 9001

- HS Code: 84223010

- Type: Volumetric Filling Machine

- Material Type: Liquid

- Feed Cylinder Structure: Multi-Room Feeding

- Filling Principle: Atmospheric Pressure

- Structure: Rotary

- Packaging Material: Plastic

- Suitable Bottle Size: 250ml~2000ml

- Control: PLC

- Filling Heads: 12-60

- After-Sales Service: Engineers Available to Overseas for Installation

- Name: Full Automatic Water Making Line

- Transport Package: Wooden Case

- Origin: Zhangjiagang City, Jiangsu Province, China

1, Model: CGF18-18-6

2, Capacity: 6000~8000bph

3, Certificate: CE

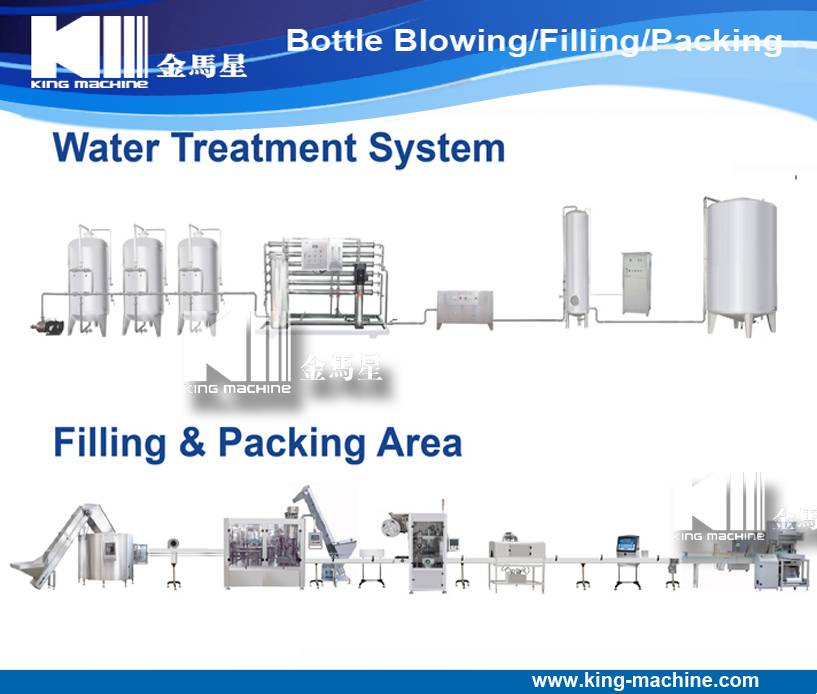

Pure Water Monoblock Filling Plant / Line / Equipment/Machine Main components:

1) driving system;

2) bottle-loading system;

3) bottle-rinsing system;

4) handing-over system between rinsing and filling;

5) filling system;

6) handing-over system between filling and capping;

7) capping system;

8) cap-unscrambling system;

9) bottle-unloading system;

10) frame;

11) electrical system.

Rinser

Drinkable water filling line

Spring cramps are used in the bottle washing process. The empty bottles can be turned over 180° Along the conveying rail. There are two times of internal and external washing, the efficiency of bottle washing is high.

Rinsing machine adopts Sky Machinery original overturn and double-opened bottle clip. Bottle clip lock the bottleneck, the material of bottle clip is SUS304, which is hygienic and durable.

Bottle clip equipped with efficient spray on nozzle. The extrusive droplet with 15° Angle ensures to wash all side of the bottle, and can save the water.

Filler

Drinkable water filling line

Filling machinery design of filling structure is reasonable and hygiene dead angle, the run of equipment is stable, it can control the material from the bottleneck, the control accuracy is within ± 2mm (subject to bottle design). The filling valve material is SUS304. The filling system has liquid level automatic control. Filling valve lift is controlled by the valve elevator, after filling valve contact the bottleneck, it starts to fill. Bottle is conveying by the wheel in the filling part.

Capper

Drinkable water filling line

Screw capping machine is most precision part in the 3-1 machine, it has a big influence to the goods stability and defective rate. Our screw capping has following feature.

Sky Machinery import of advanced technology of screw capping, improve the stability and reliability of the screw capping machine. The magnetic torque is used for screw capping. The power of screw capping can be adjusted without steps. The power of the screw capping can also be fixed, and the caps will not be damaged, the capping is reliable.

Water bottle filling equipment after-sales service:

We will send one professional engineer to install the whole line for you, but you should pay him USD 80 / DAY as salary, also include his return tickets, room, food and visa fee.

Machine guarantee time: 12 months

FAQ for machines

1. What kind of products will you produce?

2. What is the capacity(per hour) you want?

3. What kind of package, plastic bottle, glass bottle: Volume, height, neck diameter, diameter of bottle or other please inform us of details.

4. Sole machine or whole production line?

| Model | CGF18186 |

| Heads of washing,filling ,sealing | 18-18-6 |

| Production capacity (bottle/hour) | 6000-8000 |

| Suitable bottle diameter(mm) | φ =50-100 H=170 330-1500ml |

| Spraying pressure | 2~3 |

| Motor power | Main motor 2.2kw |

| Power of outer vacuum pump | 1.1 |

| O verall dimension (LxWxH) | 2460x1720x2650 |

| Weight | 3500 |

Related Products

-

High Quality Fruit Juice Making Filling and Capping Plant (RCGF40-40-12)

-

700ml fruit infuser water bottle, tritan bottle drinking water plant

-

Pet Bottled Automatic Hot Filling Juice Filling Machine for Apple, Orange Juice Plant

-

4 in 1 Automatic 5 Liter Pure Water Bottling Filling Machine

-

small yogurt processing plant, yogurt production machine with cup filling